Murai Camp Cable Repair Project

Image of cable

Overview of Project

The main objective of this project is to repair the 15m cable that was sent in by the Republic of Singapore Air Force (RSAF) personnel from Murai Camp as one of the wires had disconnected from the MIL-DTL-38999 series III straight plug 37 pin connector (D38999/26WD/35PN).

My Roles and Responsibilities

In this project, I am responsible for repairing the cable which includes developing the cable schematic in this project because the cable schematic was not given. In addition, I also needed to create a bill of materials by sourcing for the various components required such as the connectors, crimping pins, braided shield, heat shrinkable tubing, solder sleeves, cable boot, and the insertion and removal tools.

My Contributions

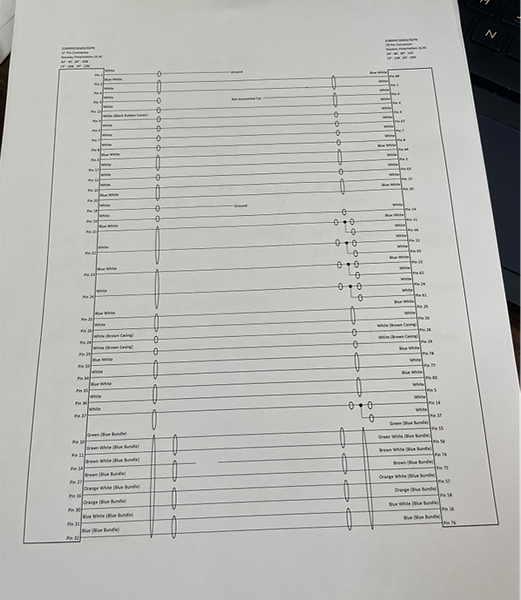

I was able to trace the connections of the pins between the two connectors using the continuity test on the digital multi-meter. I summarized my findings into a cable schematic where I labelled the wires' respective pin numbers beside each wire as shown.

Image of cable schematic

I have also sourced for the components required in this repair project, which include:

-

Braided shield (P/N: MBN0.50SV50)

-

Heat shrinkable tubing (P/N: DR-25-3/4-0-SP)

-

37-pin male straight plug connector (P/N: D38999/26WD/35PN)

-

79-pin male straight plug connector (P/N: D38999/26WG/35PN)

-

Cable boots (P/N: 202S132-25C-0 for the D38999/26WD/35PN connector and 202S152-25C-0 for the D38999/26WG/35PN connector)

-

Plug cover (P/N: D38999/32W15N for the D38999/26WD/35PN connector and D38999/32W21N for the D38999/26WG/35PN connector)

-

Size 22 D contact pins (P/N: M39029/58-360)

-

Solder sleeves (P/N: S01-01-R, S03-01-R, S03-02-R and S03-04-R).

-

Plastic insertion and removal tool (P/N: M81969/14-01)

-

Metal insertion tool (P/N: M81969/8-01) and the metal removal tool (P/N: M81969/8-02)

To summarize the cost of the components for the repair, I have created a bill of materials as shown

Image of bill of materials

Real world application of industry domain knowledge and skills in the workplace

One of the modules I took last year was Integrated Real World Project 4 (65IRP4A), and one of the projects we worked on was the Aircraft Cockpit Wire Harness Design and Fabrication (CWHDF). The main objective of this project is to provide us with hands-on experience with the assembly and fabrication of aircraft wire harnesses. In this project, the wire harness that we assembled and fabricated is identical to the Douglas A-4 Skyhawk. Furthermore, this project also allows us to try out the various tools and equipment required for the fabrication of the aircraft harness, such as the wire stripper, connector pin crimper, die, and insertion and removal tools.

In this project, I was able to apply the skills and knowledge imparted to me by my lecturers from 65IRP4A, Mr. Yee and Mr. Ong. Since I had previously used the crimper to fabricate and assemble the wire harness in CWHDF, I was able to crimp the size 22D contact pins (M39029/58-360) to the wires in this project. Furthermore, I was able to use the insertion and removal tools to successfully remove and insert the wires from the connectors.

Learning Points

I also learned how to read the datasheet for the MIL-DTL-38999 series connectors as well as how to identify the corresponding contact pin. For instance, the corresponding contact pin for the D38999/26WD/35PN – 37 pin connector and the D38999/26WG/35PN – 79 pin connector is the M39029/58-360 – size 22D contact pin.

In addition, I learned how to source and create a bill of materials for the various components required for this repair project, such as the braided shield, heat shrinkable tubing, 37-pin male straight plug connector, 79-pin male straight plug connector, cable boots, plug cover, size 22 D contact pins and the solder sleeves.

I also learned how to extract a broken contact pin from the connector. Additionally, I also learned the necessary procedures that need to be followed to repair the aircraft cables.